ATY(air texturing yarn) uses special processing technology to produce the concave and convex feel and soft touch of natural flax, but also overcome the crease of natural flax, washable, easy to care. Suitable for decorative cloth (curtain cloth, yarn release, pillow, cushion, scarf, gauze, etc.), fashion fabrics。

ATY Air texturing yarn machine for pp pet yarn filament process

1. Product Description

After drawing, the tows of FDY filaments such as nylon, polyester and polypropylene fibers are blown under the action of high-speed airflow in the nozzle, fluffy into arcs and rings, and intertwined into deformed filaments. ATY machine adopts different deformation processes to make its product air textured yarn (ATY) have wool-like, cotton-like, linen-like or silk-like appearance and feel.

2. Technical Data

| Spinnable Yarn Density | 5000d |

| Spinnable Fiber Material | Polypropylene/Polyester/Nylon |

| Spinning Package | 430*250 |

| Mechanical Speed | 150-1000m/min(Process speed depends on process parameters, nozzles and raw filament quality.) |

| Spindle Number | 24spindle/section - 288spindle/section |

| Number Of Winding Layers | 3layers |

| Section Distance | 1440mm |

| Winding Diameter | 250mm |

| Winding Shape | Bipyramid or rectangular, angle adjustment70,75,80,90 |

| Transverse Length | 195-250mm |

| Crossing Angle | Adjustable10-45 |

| Chuck Size | φ69.2 φ57.15 |

| Feeding Roller | 3pics/spindle |

| Sensor | 3pics/spindle |

| Yarn Cutter | 2pics/spindle |

| Creel Form | 4-angle fixed creel with 4 feeding positions per spindle |

| Total Power | 80KW |

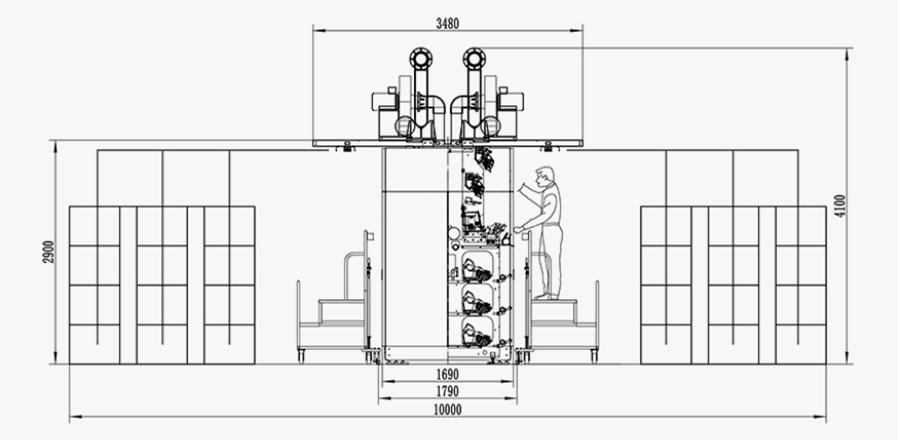

| Machine dimension(L*W*H) | 19943*10000*4100(288spindle, including creel width) |

3. Yarn Processing

ATY Air texturing yarn machine for pp pet yarn filament process

When the filament enters the nozzle at low overfeed rate, the running direction of the hot gas flows along the tow to disperse it. The tow is fixed under the effect of deformation and heat setting in the nozzle. The design of the nozzle should reduce the gas consumption and improve the intertwining effect. The Y type design can make the yarn knot stable and the length of the yarn is consistent. The jet deformed wire is not a yarn with loose ends of the fiber, but an irregular loop and a twisted filament produced by a mechanical method. The filament is formed by the filament winding and heat treatment of its adjacent filament.

4. Machine Sketch

5. Final Products:

ATY Air texturing yarn machine for pp pet yarn filament process has wool-like, linen-like and cotton-like appearance and feel, and is widely used in clothing, home decoration, car seats, umbrellas, bags, carpets, wall cloth and other textile industries or industrial puffing and dipping products.

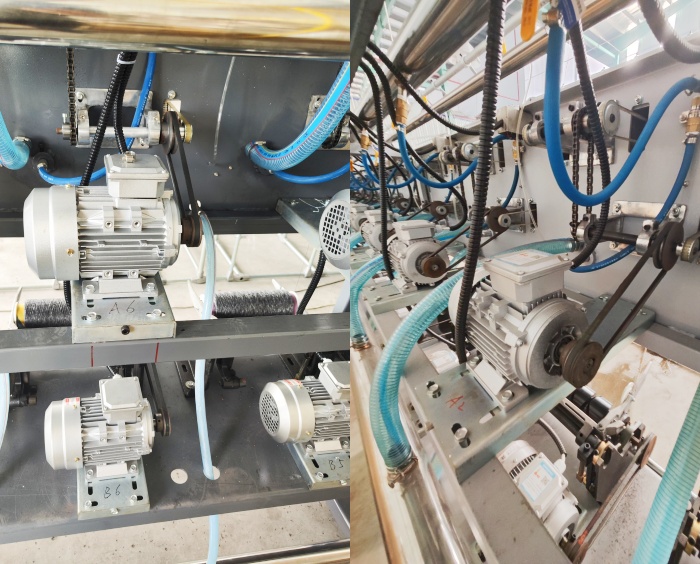

6. Machine Details

Applications

It can be used as decorative cloth for sofa cloth, table cloth, imitation linen cloth, curtain cloth, etc.

Air textured yarns used as decorative materials are mostly made by a spinning-drawing process, so that no drafting is required before the deformation process. The feed yarn is usually a melt dyed yarn.

In the case of automotive interiors, the seat cover, seat back, inner door panel and inner top panel are all made of Polyester air textured yarn. Car seats are often exposed to heat, strong sunlight, and a lot of wear. Polyester air textured yarn can meet the above requirements.

Woven Fabrics

Can be used to make ski clothes, sportswear, socks, underwear, luggage cloth, vamp cloth, etc.

The nylon air texturing yarn used to make ski clothes is the first market for air texturing yarns used as woven weft yarns.

Used as a sewing thread, it is a very special application field for polyester air textured yarn. The air textured yarn not only has high tensile strength, but also has excellent wear resistance. Due to the surface arc structure of the air-deformed yarn, the sewing thread can be processed at a speed higher than 6000 needles/main without melting or breakage.

Thick denier yarn can be used for carpets, tapestries, etc.

TEL: +86 538 899 6996

E-MAIL: sales@jiameitech.com