We are professional manufacturer engaged in multifilament chemical fiber spinning machinery with good experience of 30 years. Our main products include FDY、POY、BCF、ATY multifilament spinning line. FDY PP yarn spinning machine is widely used in the fields of rope curtain tie back, fiber reinforced concrete, sewing thread, webbing, wig, rope, etc.

1. Product Description

Polypropylene rope curtain tie back yarn making plant

1) Low power consumption, 1-1.2kw/1kg yarn

2) Fast asscmble and trainning, professional engineer 10-15days

3) Reasonable design to make high tenacity yarn 7-7.5g/d

4) Easy operate, PLC control + touch screen

5) It require the building roof 7m

6) Electric parts from famous JAPAN brand

7) The pp multifilament is widely used for making rope curtain tiebacks, filter cloth, fiber reinforced concrete, sewing thread, webbing, rope, etc.

2. Technical Data:

| Item | Unit | Model | ||||||

| JM261 | JM241 | JM181 | JM161 | JM141 | JM131 | JM121 | ||

| No. of pos | Pos. | 2 | 2 | 1 | 1 | 1 | 1 | 1 |

| titer | dtex | 150-4500 | ||||||

| No. of ends/pos. | Spinner/pos | 6 | 4 | 8 | 6 | 4 | 3 | 2 |

| Spinneret | mm | 160 | 160 | 160 | 160 | 160 | 140 | 140 |

| Metering pump | cm3/rpm | 12cc/rpm | ||||||

| Winding speed | M/min | 2000-2400 | ||||||

| Output/24hr(900d) | kg | 3456 | 2304 | 2304 | 1728 | 1152 | 864 | 576 |

| Dia. of screw | mm | 120 | 105 | 90 | 90 | 70 | 70 | 55 |

| L/D | 30:1 | |||||||

| Drive power | kw | 90 | 40 | 30 | 42.37 | 35 | 35 | 32 |

| Heating power | kw | 190 | 90 | 75 | 93.5 | 90 | 62.5 | 60 |

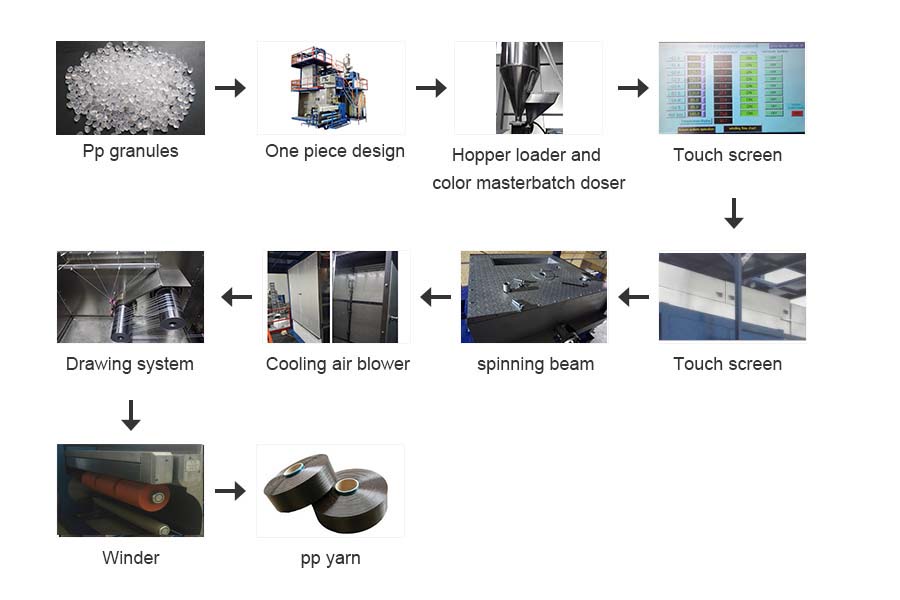

2. Production Process:

Technical process of Polypropylene rope curtain tie back yarn making plant:

Chips→ extruder→ extruding head →melt pipe with static mixer→ spinning beam with oil heating →quenching delay→ quenching chamber → oiling system → feeding roller →migration nozzle→ four pairs of hot godet rollers→ inter lacing jets→ take-up winder →final product

3. Final Products:

Our equipment is widely used in the industrial fields of curtain tiebacks, filter cloth, construcion fibre, sewing thread, webbing, braiding/knitting products, rope, fishing net and narrow fabrivc etc.

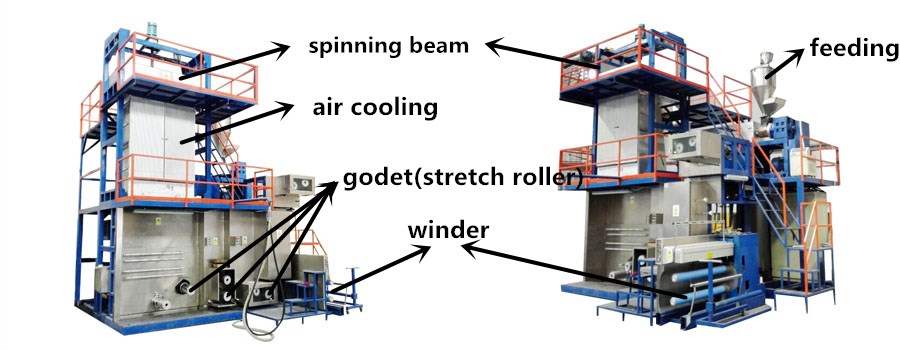

4. Machine Parts:

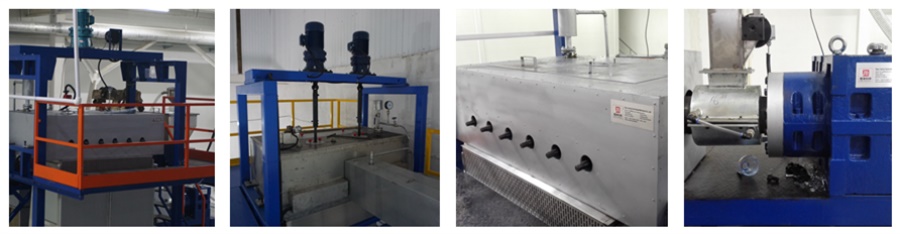

Extruder Part of FDY PP multifilament yarn spinning machine:

1. Automatic hopper loader

2. Extruder head (with measuring head)

3. Spinning beam

4. Metering pump

5. Spinneret + packs

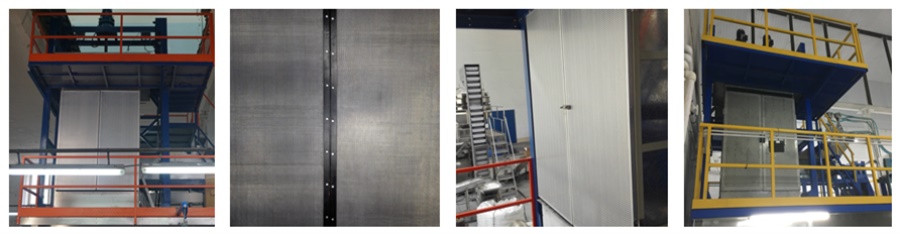

Air Cooling Blower of FDY PP multifilament yarn spinning machine:

1. Blowing area:W 1250mm*H1800mm

2. With filter

3. With air fan,frequency control

4. It has several layers

5. It can be opened from the side. It's very convenient

High Speed Winding Machine of FDY PP multifilament yarn spinning machine:

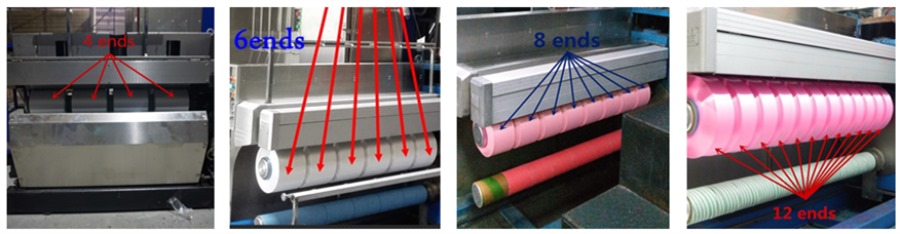

1. 3 ends, 4 ends, 6 ends, 8 ends, 12 ends

2. 1600-2600m/min

3. Paper bobbin size:Φ110×Φ125×230mm

4. Max spool dia: Φ420mm , Traverse mode

5. Famous winder brand

6. Packing & Delivery

7. Installation & Training

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* With online device, our team is 24hr at your service.

After-Sales Service

* Come engineer help set up machine, take 12-15 days for assemble and trainning. 3-4 days for set up, 5-6 days for training.

* The customer should prepare 3-5 workers for learn and operate the machine.

* With online device, our team is 24hr at your service.

TEL: +86 538 899 6996

E-MAIL: sales@jiameitech.com