1. Product Description

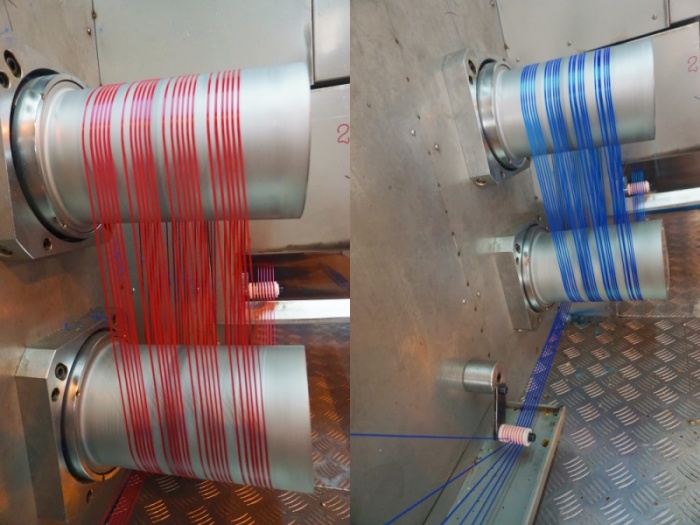

JM281 industrial yarn FDY spinning system

1) 2 pos, 8ends

2) Titer: 600-3000D

3) Winding Speed: 1500-2500m/min

4) Capacity: 6000kg/d

2. Production Process:

Technical process of JM281 industrial yarn FDY spinning system:

Chips→ extruder→ extruding head →melt pipe with static mixer→ spinning beam with oil heating →quenching delay→ quenching chamber → oiling system → feeding roller →migration nozzle→ four pairs of hot godet rollers→ inter lacing jets→ take-up winder →final product

3. Final Products

JM281 industrial yarn FDY spinning system produces PP/PET/PA/Polypropylene/Polyester/Nylon multifilaments for varied applications like Geo-Textile, Failter cloth, Lifting Belts, Cables, FIBC jumbo bags, wig, construction reinforce fiber, sewing thread, fishing net, narrow fabrivc, webbings and slings, braids, ropes and technical applications.

4. Installation & Training

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* With online device, our team is 24hr at your service.

After-Sales Service

* Come engineer help set up machine, take 12-15 days for assemble and trainning. 3-4 days for set up, 5-6 days for training.

* The customer should prepare 3-5 workers for learn and operate the machne.

* With online device, our team is 24hr at your service.

TEL: +86 538 899 6996

E-MAIL: sales@jiameitech.com